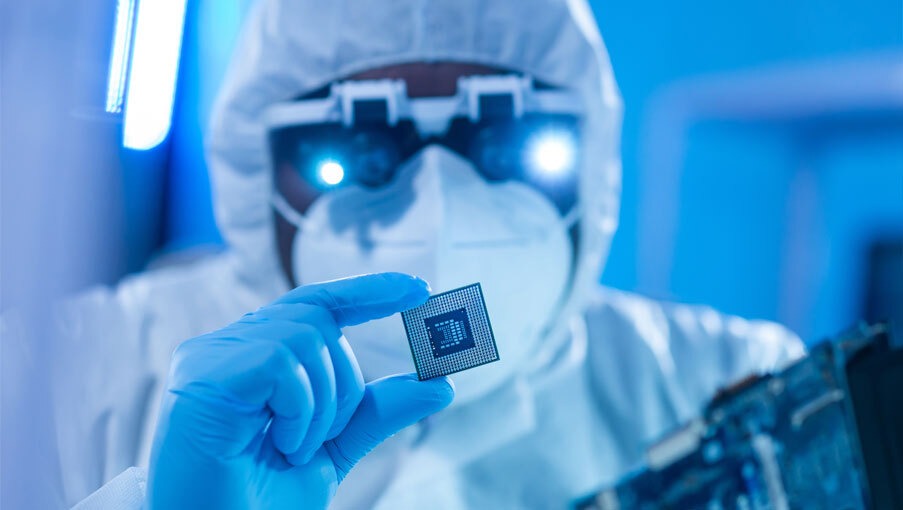

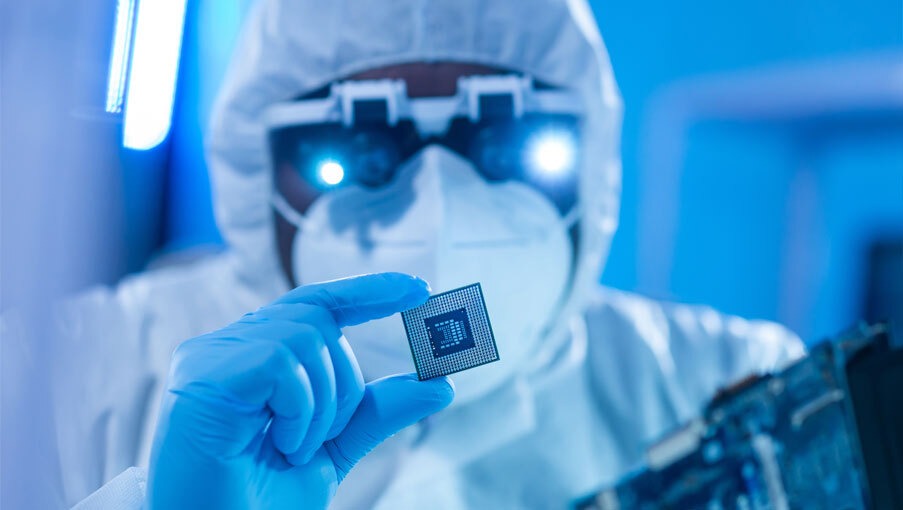

Multi-Die Solutions

Embracing the trend of multi-die solutions, we have experienced engineers with technical expertise to drive development of integrated circuits that incorporate multiple semiconductors dies on a single package. This approach enhances performance, reduces power consumption, and enables the creation of more compact and efficient devices.

Domain-Specific Architecture

A more hardware-centric approach is to design architectures tailored to a specific problem domain and offer significant performance (and efficiency) gains for that domain, hence, the name “domain-specific architectures” (DSAs), a class of processors tailored for a specific domain.

Over the past ten years, we have witnessed a noteworthy shift in the landscape, with approximately 150 start-ups collectively focusing on hardware innovations. This stands in stark contrast to the previous decade when hardware investments took a backseat in favor of software-centric approaches. As we embrace this hardware-centric paradigm, our commitment to innovation and client success remains at the forefront of our endeavours.

Open Source Architectures

Hennessy and Patterson, in their 2018 Turing Lecture, expressed enthusiasm about the potential of open architectures, particularly highlighting RISC-V, to accelerate innovation and reduce costs. Open Instruction Set Architectures (ISAs), like RISC-V, provide companies with increased flexibility, simplicity, and reduced power consumption. They also contribute to the development of more secure architectures. We have been actively engaged in an internal project rooted in open source, scheduled for completion in the near future. Our team comprises experienced engineers with expertise in various aspects, ranging from application understanding to identifying an open-source processor and customizing it to meet our specific requirements.

Chiplets

Emphasizing chiplet architecture, we contribute to our clients’ projects, whether operating from offshore development centers in our office or having our engineers work directly at the client’s office. The end is to contribute to the modularization of semiconductor designs, enabling independent development and integration of smaller chiplets. This approach promotes flexibility, scalability, and efficient resource utilization. These specialized, modular chips can be combined to create a complex, integrated System-on-Chip (SoC) using die-to-die interconnects on the same substrate. Chiplets, produced at different process nodes, can be reused in various designs, shortening system development cycles and optimizing costs by creating targeted SoCs without unnecessary components. Additionally, chiplet architecture reduces power consumption and enhances yields compared to larger and more complicated architectures. Advanced packaging technologies, such as 3D integration, are employed to ensure high-speed, low-latency communication between chiplets.

AI-Driven Design: Hardware is a Differentiator in AI

In compute, there is a predicted shift from traditional CPUs and GPUs to domain-specific accelerators (DSAs) and application-specific integrated circuits (ASICs). Memory technologies, such as High Bandwidth Memory (HBM) and larger on-chip memory, are enhancing AI application processing speed while minimizing power requirements. Additionally, storage is evolving with the adoption of new forms of Non-Volatile Memory (NVM) like Magneto Resistive Random-Access Memory (MRAM), Resistive Random-Access Memory (ReRAM), and Phase Change Memory for improved efficiency and performance. This transformative landscape represents a historic opportunity for semiconductor companies in terms of growth and technological leadership.

Analog In-Memory Computing

Since the early days of the digital computer age, the processor has been separated from the memory. Operations performed using a large amount of data require a similarly large number of data elements to be retrieved from the memory storage. This limitation, known as the von Neumann bottleneck, can overshadow the actual computing time.

In-memory computing – doing compute processing in the memory fabric itself in analog manner – completely changes this philosophy of Von Nuemann architecture. For example AI chips involve heavy replication of multiply add operations of large vectors – in analog world Kirchoff law can be used to perform the multiplication. Bits are stored in resistive non volatile memory as analog values.

It can consume fraction of power and fraction of time to get this done. Our company is actively involved in harnessing and advancing in-memory computing technologies. This engagement takes place either by collaborating with clients at various sites or through offshore development centres (ODC’s).

Packaging

Semiconductor packaging solutions aim to encase integrated circuits (ICs) or chips, ensuring protection, electrical connectivity, and efficient thermal management. Diverse packaging techniques cater to specific application needs, including traditional Single-Chip Packaging such as Dual In-line Package (DIP) and Quad Flat Package (QFP), Multi-Chip Packaging with Multi-Chip Modules (MCM), and Surface Mount Technology (SMT) options like Ball Grid Array (BGA) and Chip on Board (COB).

System-in-Package (SiP) enables the combination of functional blocks for miniaturization, while 3D Packaging utilizes Through-Silicon Via (TSV) and Package-on-Package (PoP) for space-saving and improved interconnectivity. Advanced options like Fan-out Wafer-Level Packaging (FOWLP) and Heterogeneous Integration enhance performance and efficiency. Additionally, Flip-Chip Packaging, involving Flip-Chip Ball Grid Array (FCBGA), optimizes electrical performance. The use of both Organic and Inorganic Substrates, along with Wafer-Level Packaging (WLP) carried out before singulation, contributes to efficiency. Ongoing advancements in semiconductor packaging, including materials, 2.5D and 3D integration, and heterogeneous technologies, are noted, and we are dedicated to work on advanced packaging solutions to improve thermal management, reduce form factors, and enhance overall system reliability. This commitment includes the deployment of skilled engineers who possess expertise in this field, enabling them to lead projects for clients from the initial stages to their final completion.

Related blogs

In today's rapidly evolving semiconductor industry, the demand for efficient, scalable, and customizable design flows...

API Productization API productization involves transforming APIs into full-fledged products with life cycles, pricing and...

Automotive Infotainment – HMI : Infotainment systems have been evolving rapidly, integrating entertainment, navigation, communication,...